ProductPRODUCT

Featured products

Contact Us

- QICEQUIP

- 5mm-1500mm

- Shenzhen China

- Spot

Thermostatic Heater ,Heating equipment class to aluminium plate, copper plate, stainless steel plate, ceramics, transparent glass and other electrical heating materials, precise temperature control, the use of temperature range from room temperature to 900 degrees adjustable. Widely used in the LED industry, electronics manufacturing, industrial industry, biology, scientific research laboratories and other fields, can be customised according to customer requirements.

- Hot Plate

一. Item description:

1.Adopted by original Yudian Automation PDI economic type temperature controller, its high-accuracy, operation is safe, simple, clear and convenience.

2.Adopted by original high-quality AC solid-state relay, long lasting as 100 times of the common contact relay.

3.Adopted by multiple high-quality metal heating pipes, maintenance is convenience and low failure-rate.

4.The aluminum top surface is high thermal conductivity, heat fast and evenly.

5.The whole case is made by high-quality SUS304 stainless to ensure it against from rusted and peeling off in the usual condition.

6.The control system is equipped with a cooling fan and a cooling window to ensure that the internal components do not overheat;

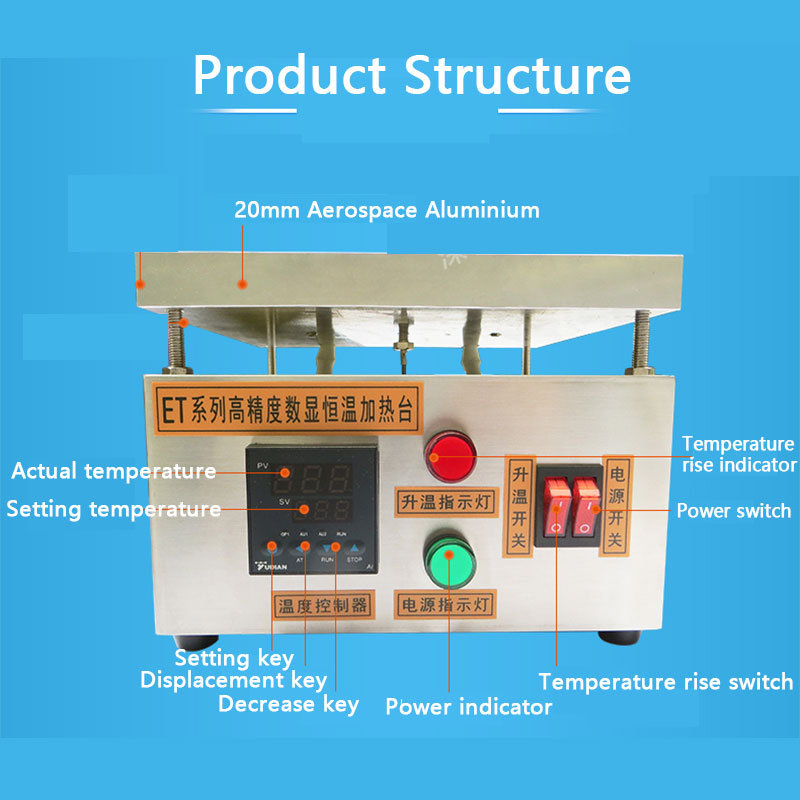

Heating-table-product-structure

二. Specfation

Power supply: 220V (50HZ) (100VAC optional); Controllable temperature range: Basic (room temperature ~ 350°C); High temperature (room temperature ~ 450°C), Ultra high temperature (room temperature ~ 500°C), Stainless steel (room temperature ~ 700°C), Highly conductive ceramic (room temperature ~ 800°C), Vacuum heated (room temperature ~ 1,000°C), Each model is available in a single unit (standard model), Each model has a unit type (standard), a split type (F type), a cover type (B type), a protective cover type (G type), and a vacuum heating type (ZK type).

| Item NO. |

Heat Generating Plate Spec. |

Power |

Net Weight |

|

ET-1010 |

100x100x20mm士1 |

500W (MAX) |

4.0 Kg |

|

ET-1515 |

200X150X20MM士1 |

600W(MAX) |

5.0 kg |

|

ET-2020 |

200x200x20mm士1 |

900W (MAX) |

5.2 Kg |

|

ET-3020 |

300x200x20mm士1 |

1500W (MAX) |

6.5 Kg |

|

ET-3030 |

300x300x20mm士1 |

1600W (MAX) |

7.0 Kg |

|

ET-3625 |

360x250x20mm士1 |

1800W (MAX) |

8.5 Kg |

|

ET-400 |

400x300x20mm士1 |

2000W (MAX) |

12.5 Kg |

|

ET-5035 |

500x350x20mm士1 |

2700W (MAX) |

21.3 Kg |

|

ET-6040 |

600x400x20mm士1 |

3200W (MAX) |

22.5 Kg |

|

ET-8060 |

800x600x25mm士1 |

8600W (MAX) |

60 Kg |

|

ET-100100 |

1000x1000x25mm士1 |

1500W (MAX) |

150 Kg |

|

ET-150130 |

1500x1300x30mm士1 |

2700W (MAX) |

300 Kg |

三. Application filed

Electronic industrial bonding sealing and application heating.

LED industrial aluminum base welding and maintenance

mold core pre-heating

Essential equipment at the laboratory in various industrials such as biology, genetics, medicine and environment etc.

四. Application Instruction

Plug in the power and turn on the POWER switch while the RED indicator light constant light, its means the device has being powered.

Turn on the HEATING switch and the device is starting then, GREEN indicator light constant light, it’s means the device is heating up; sparkling means it has been into the constant temperature while workstation is being recycle heating up.

Once it finish using, please turn off the HEATING switch first and the device will be stopped heating, while the RED indicator light are still constant light in order to reminding the device are still working and please don’t touch the work surface. Wait for the work surface being cool down (suggesting after an hour) and torn off the POWER switch then.

五. Attention:

Voltage must be 220V, please use the 3 pole socket which is connect to the earth and with anticreeping switch as well.

Please don’t open the case or switch any wire position unless you are the specific operation.

Hand touch is prohibited in case to avoid burn.

Please unplug the power supply when the people away or device has being long term idle.

Please keep the vent hole clean since the device has been cooperated with fan cooler,

Please make sure it has unplugged from the power source when the fuse needs to be replaced for safety.

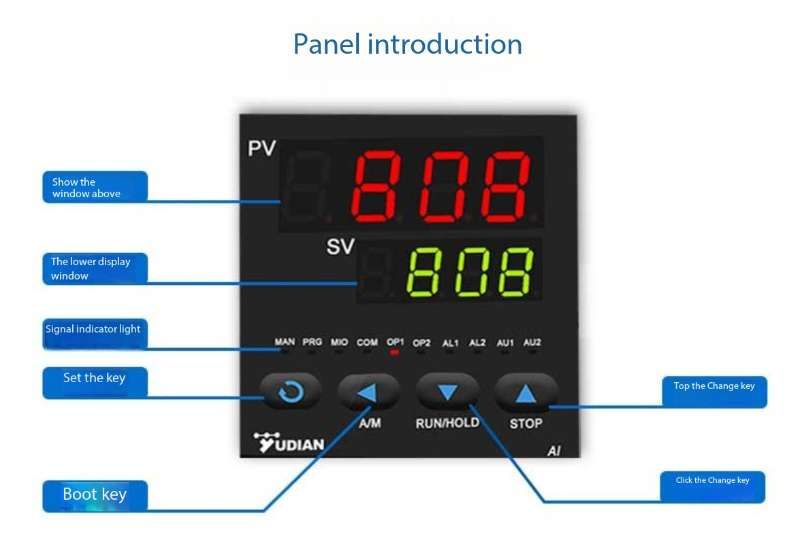

六. Control panel illustration

| PV |

measurement value / model value display |

< |

data |

|

SV |

ET value / model content value display |

∨ |

data reducing |

|

OP1 |

out put |

∧ |

data increasing |

|

AU1 |

alarm 1 |

0 |

model ET ( enter) |

|

AU2 |

alarm 2 |

七. Parameter ETting

Press the key “0” at few seconds to enter the following table:

| Name | illustration | ETting range | Factory Defult |

| HIA | Maximum alarm | 0-999 | 999 |

| LOA | Minimum alarm | 0-999 | -199 |

| HDA | tolerance maximum alarm | 0-999 | 999 |

| LOC | parameter modify level | 0-255 | 0(modify prohibited) |

ET value ETting: Press the key ∧,∨,< to modify the control value which is showing at the display window under the default situation, press the key ∨ for value reducing, press the key ∧ for value increasing, the dot sparkly with the number which position switched( sparkly like cursor). Press down for quick increase / reduce value, and the value will be speed up while the position of the dot rightward switch. Press the key < to move and modify the position of the value (cursor). Press the key ∧ or ∨ to modify the value which is sparkly, control convenience.

Automatic adjustable (AT) operation, available with Automatic (AT) operating to confirm the PID adjustable parameter when use AI agronomical PID control. The AT parameter shows up after press the key < at 2 seconds under the default situation. Press the key ∧ to modify the OFF to ON which is shown at the bottom display window, the Automatic Adjustable operation will be start by press the key “O” to confirm. At the same time, the letter “AT” will be sparking at the display window which is at the bottom of instrument panel, the result of the suitable PID parameter for the current condition will be counted automatically by the local micro CPU of the instrument panel, and it will be exterminated automatically from the AT operating. Press the key < at another 2 seconds to switch up the AT parameter from ON to OFF and confirmed by press the key “0” to give up the AT operating. (Remarks: The system parameter value are totally different within the different ET value, SV value modify are prohibited while the AT operating in process. The control result might be not the best once the AT operation finished, it will be got the best result after use in a while

Nonstandard specification is available to booking with 5~7 working days lead-time

八, Guarantee

12 months guaranteed for the complete device (6 months for heating pipe) beyond human control.

Lifetime beneficial service after guarantee.

Note:

Please make sure the connector plug is plug in fastened, no shaking movement, otherwise the power socket will be burned by the spark.

The temperature might be 3-5 degrees higher than the ETting number and it will be back to it after few minutes, this feature could be increase the uniformity of heating panel temperature.

Since the heating panel is machined goods, there has some machine oil left at the screw hole and it would be some smoke with smell comes up after burning by the high temperature, this is normal phenomenon and will be disappeared after a period.

Please ignore the noise when this equipment running, it’s because of grating that the heating pipe rubs against with panel during the situation of substances expand when heated and contract when cooled.

There are 2 fuses inside the equipment to ensure the safety.

It has been took 24 hours for burn-in test before out-going of the factory, please don’t change the default parameter without authorized, otherwise our association will take no responsibility and liability.

Our advantage

24-hour service

Foreign trade cattle is based on the premise of big data analysis

Unlock the goods

Foreign trade cattle is based on the premise of big data analysis

24-hour service

Foreign trade cattle is based on the premise of big data analysis

Convenient search

Foreign trade cattle is based on the premise of big data analysis

TEI brake pad brake disc brake

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification

TEI brake pad brake disc brake

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification