ProductPRODUCT

Featured products

Contact Us

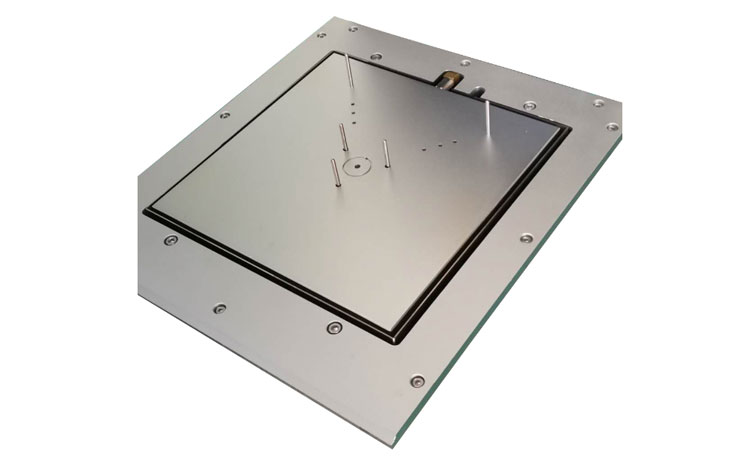

Vacuum Flow Atmosphere Lift-Type Baking Machine features a hard anodized aluminum corrosion-resistant heating panel. The heating panel offers excellent uniformity, high temperature control precision, minimal deformation, and corrosion resistance. It also boasts rapid heating, programmable segmented temperature control, and precise temperature regulation. Equipped with a 7-inch full-color touchscreen, advanced industrial PLC control enables automatic lifting, timed sample retrieval, adjustable pin height for non-contact baking, and heating experiments for various samples under vacuum or nitrogen environments.

Vacuum Flow Atmosphere Lift-Type Baking Machine features a hard anodized aluminum corrosion-resistant heating panel. The heating panel offers excellent uniformity, high temperature control precision, minimal deformation, and corrosion resistance. It also boasts rapid heating, programmable segmented temperature control, and precise temperature regulation. Equipped with a 7-inch full-color touchscreen, advanced industrial PLC control enables automatic lifting, timed sample retrieval, adjustable pin height for non-contact baking, and heating experiments for various samples under vacuum or nitrogen environments.

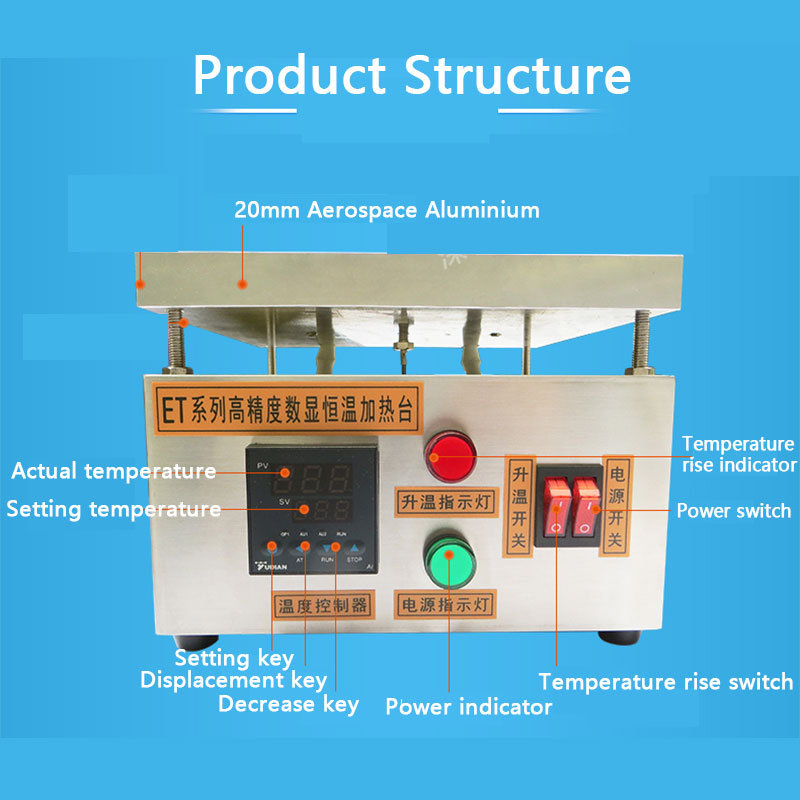

Vacuum Baking Machine Product Features:

1. Heating panel: Hard anodized aluminum corrosion-resistant heating panel. Equipment withstands high temperatures without discoloration. Custom ceramic-coated heating panels available for enhanced corrosion resistance and oxidation prevention.

2. Surface flatness: ±0.02mm

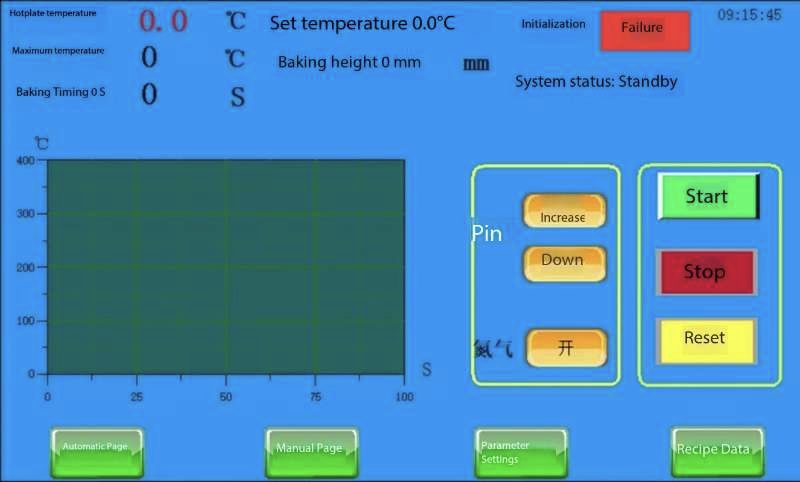

3. 7-inch full-color touchscreen with advanced PLC control, achieving temperature control accuracy of ±0.2℃

4. Digital vacuum gauge: 750Pa vacuum level with direct, precise display

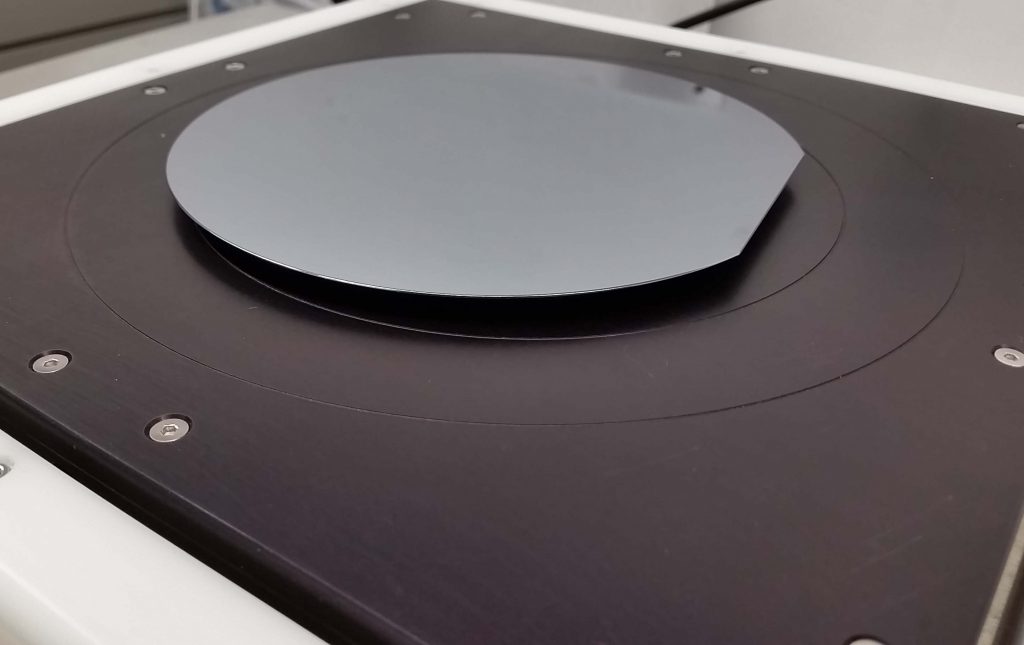

5. Protruding baking mode with adjustable lift height: 0-30mm range, electric pin height resolution: 0.1mm

6. Pins compatible with circular or square substrates exceeding 40mm diameter or inscribed circle diameter

7. Utilizes long-life heating elements with high thermal uniformity

8. Capable of linear program temperature control, equipped with high-precision digital temperature controller for high control accuracy

9. Stainless steel housing with silver-film surface treatment, resistant to oxidation and discoloration. Sleek and elegant appearance, suitable for various laboratory operations.

10. Layered structure provides effective insulation, significantly protecting electrical components. Independent circuit control for heating output enhances operational safety.

11. Perimeter heat shields reduce accident risk. Insulated design keeps control box and components distant from heat source.

12. Independent circuitry for over-temperature shutdown + audible alarm (separate thermocouple-controlled power cut + alert) enhances safety.

13. Nitrogen input controlled by dedicated valve. Outlet flow regulated via flow control valve.

14. Equipped with vacuum suction functionality.

15. Features a heat radiation protective cover for enhanced baking uniformity.

16. Compact design fits easily into glove boxes. Customizable viewing window on the equipment lid enables real-time monitoring during experiments.

Vacuum Lift-Type Baking Machine Technical Specifications:

■ Model: QC-220-ZK

■ Heating panel dimensions: 220×220 (mm) (Limit pins compatible with 4“, 6”, 8″ wafers)

■ Electric lifting pin height adjustment: 0-40mm

■ Voltage: 220V; Power: 2100W

■ External dimensions: 50×48×38 (cm)

■ Temperature Control Range: Room Temperature – 450°C

■ Temperature Resolution: 0.1°C

■ Temperature Control Accuracy: ≤±0.5°C

■ Temperature Uniformity:Room Temperature – 200°C: ±1% 200°C – 450°C: ±1-2%

■ Programmable recipe storage with 8 heating stages (programmed ramp rate 10℃/min, natural cooling)

■ Hard anodized aluminum corrosion-resistant heating panel

■ 7-inch full-color touchscreen with advanced PLC control, featuring timer alarm, programmable temperature settings, and real-time display

■ Hard anodized aluminum corrosion-resistant heating panel

■ Porous uniform gas flow design with manual pressure regulation via “pressure adjustment valve”

■ Vacuum range: 750 Pa (includes vacuum pump -0.1 MPa or 1.5 mba)

■ Nitrogen pressure: 0.2-0.8 MPa

Operating Procedure for Flow Atmosphere Vacuum Heating Platform

The flow atmosphere vacuum heating platform operation procedure was independently developed by Shenzhen Bangqi Chuangyuan Technology Co., Ltd. It is suitable for processes involving semiconductor silicon wafers, microscope slides, wafers, substrates, ITO conductive glass, etc., for surface coating, film drying, and curing after plate making. The heating plate offers high temperature stability and excellent repeatability. It can be used for production, research, and teaching in industrial plants, research institutions, and educational units. This equipment employs a PID temperature control system for automatic temperature measurement and regulation. It features an 8-stage automatic heating process, delivering fast, uniform drying speeds with high temperature control precision. It is capable of sustained, stable operation over extended periods.

Flowing Atmosphere Heating Function:

1. Open the outer cover, place the substrate inside, set the temperature control program, close the outer cover, and tighten the two cover clamping devices.

2. Open the inlet valve, adjust flow rate to x ml/min, open the outlet valve, and maintain for x min.

3. Press the “Start Switch” to initiate the temperature control program. Heating and timing commence. Open the “Nitrogen Switch” to maintain gas flow. Use the “Exhaust Switch” to circulate chamber atmosphere and vent gases.

4. Upon completion, the buzzer flashes and sounds twice. The touchscreen displays: “Heating complete. Remove product.” After the temperature control program ends,

close the “Nitrogen Switch” and “Exhaust Switch.”

5. Loosen the two lid clamping devices and open the outer lid.

Vacuum Heating Function

1. Confirm the equipment’s inlet valve “Nitrogen Switch,” outlet valve “Exhaust Switch,” and “Vacuum Switch” are in the closed position.

2. Open the outer cover, place the substrate inside, set the temperature control program, close the outer cover, and tighten the two cover clamping devices.

3. Turn on the vacuum pump for x seconds, then activate the “Vacuum Switch” to initiate chamber evacuation until vacuum level reaches y Pa.

4. Press the green “Start Switch” to initiate the temperature control program, keeping the vacuum pump operational.

5. Upon program completion or time expiration, the panel buzzer flashes and emits two warning tones. The touchscreen displays: “Heating complete.

Remove product.“ Shut off the vacuum pump and slowly open the inlet valve ”Nitrogen Switch” until vacuum pressure reaches 0 Pa.

6. Loosen the two lid clamping devices, open the outer lid, and remove the substrate.

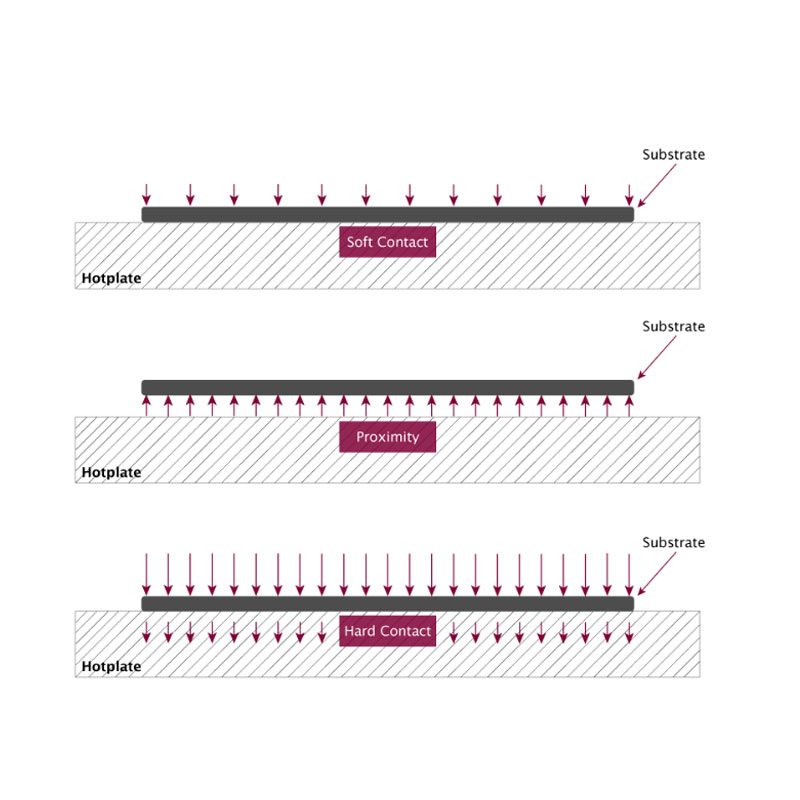

Three bake styles exist Hot Plates: proximity bake, soft contact bake and hard contact bake. These may be used in combination to further refine your baking process. The following section will discuss these methods and the advantages of each.

PROXIMITY BAKE

![]()

In this method, substrates float on a pillow of nitrogen that is blown through orifices in the chuck surface. A combination of heated gas and radiant heat from the chuck heats the substrate. This slower heating of the substrate reduces blistering and cracking of films incorporating fast-drying solvents.

HARD-CONTACT BAKE

![]()

Hard-contact bake represents the most accurate baking method for hotplates. Vacuum ports in the chuck hold the substrate securely in place. This method insures bake uniformity and minimizes bowing and warping of the substrate.

A quicker warm-up and more efficient heating produces faster throughput in shorter bake times. Selecting the “VAC” (vacuum bake) method initiates the hard-contact bake cycle-the preferred bake method.

SOFT-CONTACT BAKE

![]()

Gravity alone holds the substrate against the surface of the chuck. While this represents the least accurate bake style, this method finds some use as an intermediate style, between the hard-contact and the proximity bakes, as a multiple step warm-up.

Our advantage

24-hour service

Foreign trade cattle is based on the premise of big data analysis

Unlock the goods

Foreign trade cattle is based on the premise of big data analysis

24-hour service

Foreign trade cattle is based on the premise of big data analysis

Convenient search

Foreign trade cattle is based on the premise of big data analysis

TEI brake pad brake disc brake

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification

TEI brake pad brake disc brake

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification