ProductPRODUCT

Featured products

Contact Us

- POWER BATTERY

- China

- Three months

- Mass supply

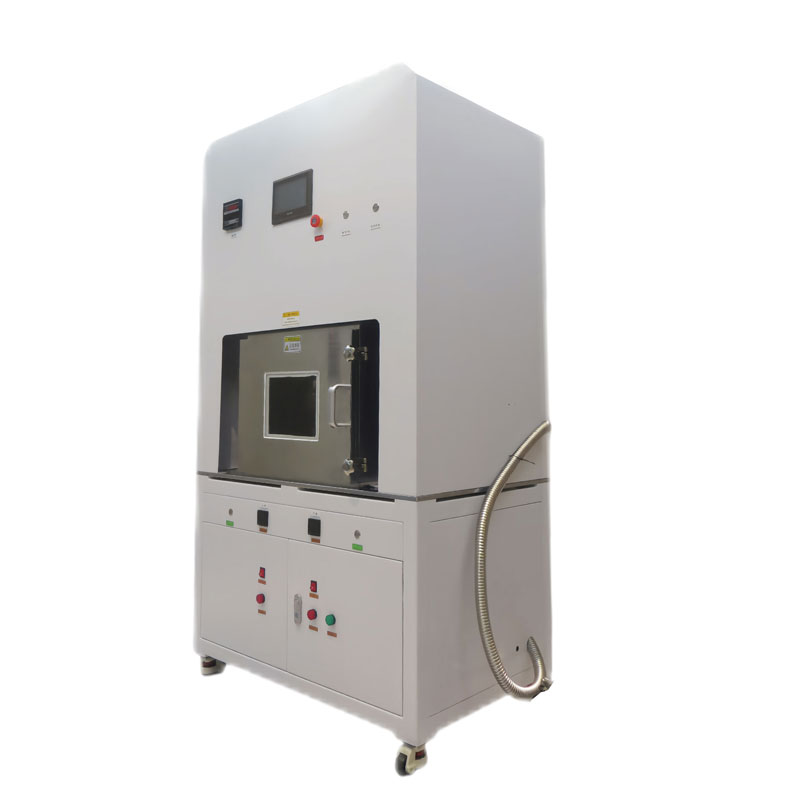

QC-2020 Vacuum Hot Pressing Forming Machine is widely used for bonding hard plastic chips such as PMMA, PC, PP, COP, COC, BOPET, CBC, resin (part), polyethylene (part), etc. Stable heating with maximum temperature of 350 degrees Celsius. Heating time and temperature can be precisely controlled. Visualizing the temperature change curve can achieve the experimental purpose more intuitively.

QC-2020 Vacuum Hot Pressing Forming Machine is widely used for bonding hard plastic chips such as PMMA, PC, PP, COP, COC, BOPET, CBC, resin (part), polyethylene (part), etc. Stable heating with maximum temperature of 350 degrees Celsius. Heating time and temperature can be precisely controlled. Visualizing the temperature change curve can achieve the experimental purpose more intuitively.

The Vacuum Hot Pressing Forming Machine designed for the preparation of microfluidic chips is specifically used for bonding plastic chips (such as PMMA, PC, COC, etc.) to achieve chip encapsulation and integration. This bonding machine employs vacuum hot press technology, characterized by high efficiency, precision, and reliability, making it suitable for various packaging and integration requirements.

- Vacuum Heat Press Machine

The Vacuum Hot Pressing Forming Machine is suitable for various microfluidic chip preparation needs, especially for bonding applications involving plastic chips. This product is characterized by efficiency, precision, and reliability, providing a high-quality solution for chip preparation and packaging.

The QC-2020 vacuum hot press bonding machine can meet vacuum needs and adjust the pressure range at any time. Ten-segment heating control. The simple and intuitive color LCD touch control screen makes your work efficiency one step faster.

The QC-2020 Vacuum Hot Pressing Forming Machine is commonly used for thermal bonding of microfluidic chips such as PMMA (acrylic), PC (polycarbonate), PP (polypropylene), COP (cyclo olefin polymer), COC (cyclo olefin copolymer), etc. Pressure seal.

Vacuum Hot Pressing Forming Machine

Related processing business:

1..R&D, manufacturing and sales of vacuum hot press bonding machines (mainly for medium-low and high-temperature bonding of plastics, silicon wafers, quartz and other substrates)

2.Microfluidic chip (PMMA\PC\PP\COC\COP\PEI and other materials) processing and sealing (hot pressing/adhesive/laser/ultrasonic)

3.Mold injection molding of plastic-based material chips.

4. Batch sealing of plastic-based chips (hot pressing process)

The Vacuum Hot Pressing Forming Machine Has Several Main Features

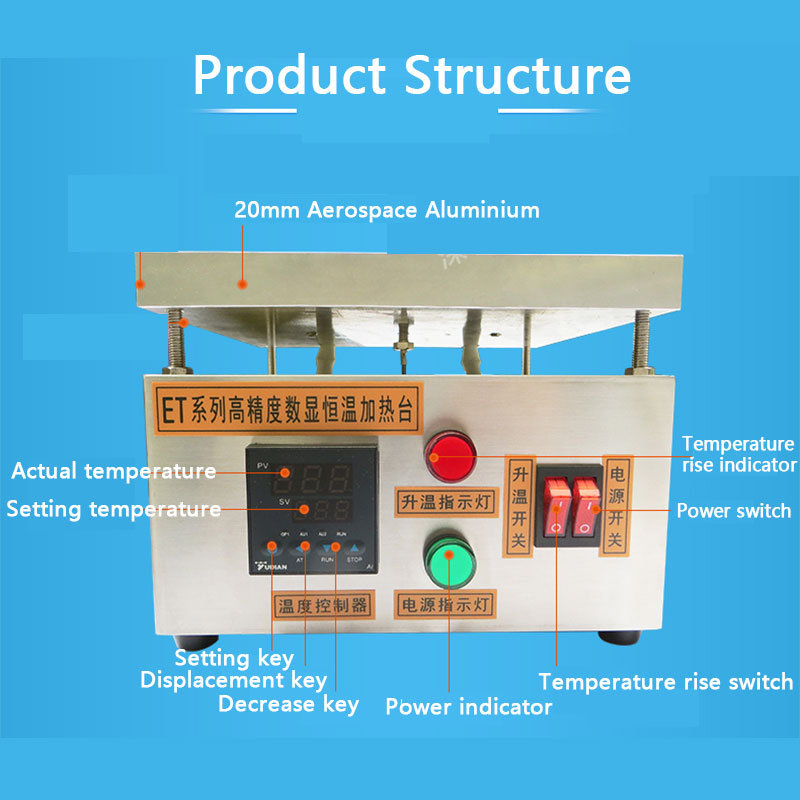

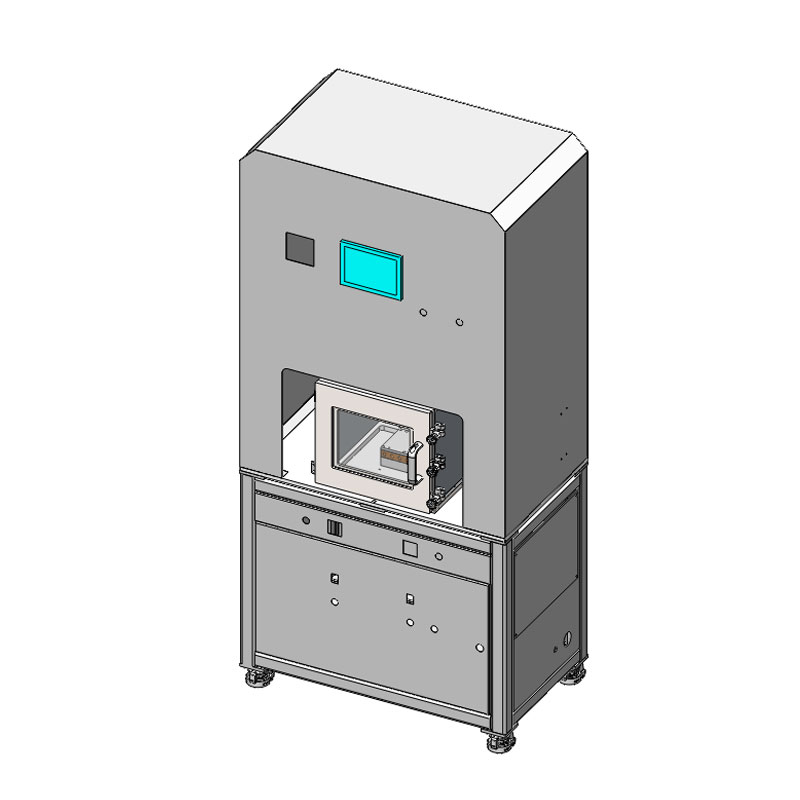

Vacuum Hot Press Machine Design Drawing

Vacuum Hot Press Technology

The bonding machine employs vacuum hot press technology, ensuring high-quality bonding results. The vacuum environment eliminates bubbles from the air, preventing damage to the chips during bonding. The heat and pressure ensure complete fusion between the materials, forming a strong bond.

Automated Control

The machine features an advanced automated control system, allowing precise control of bonding parameters and automated operations. Users can easily set bonding parameters, significantly enhancing production efficiency and quality.

High Precision and Stability

The machine utilizes high-precision and highly stable mechanical and electronic components, enabling high-precision bonding operations to ensure the quality of the bond between chips. Its stability is also high, meeting the requirements of long-duration continuous operation.

Diverse Bonding Modes

The machine offers diverse bonding modes to accommodate various chip materials and bonding requirements. For instance, users can choose different parameters such as temperature, pressure, and time to adapt to different bonding materials and sizes.

Vacuum bonding machine

Technical parameters of QC-2020 fully automatic Vacuum Hot Pressing Forming Machine

Maximum temperature rise: 350 degrees Celsius (sustainable operating temperature)

Pressure range: 0~5KN (500KG) (optional up to 4 tons)

Effective heating platform: 200mm*200mm (larger sizes can be customized)

Heating platform material: Highly conductive ceramic heating plates

Pressure source: servo electric cylinder (stroke 150mm)

Pressure setting method: intelligently set 10-segment values on the screen

Pressure Monitoring: High-Precision Pressure Sensor

Pressure display accuracy: plus or minus 0.05KN

Temperature control range: room temperature ~ 350 degrees Celsius

Temperature control accuracy: ±1% degree Celsius

Maximum heating rate: 20 degrees Celsius/minute

Vacuum degree: 2.5Kpa (standard oil-free vacuum pump)

Overall dimensions: 850 (length) * 680 (width) * 1800 (height) mm

Weight: 200KG –400kg

Rated voltage: AC220V/50HZ

Rated power: 2.5kw

Touch screen size: 12-inch color display

Temperature parameter setting: ten-stage intelligent temperature control

Shenzhen Qicequip Intelligent Equipment Co. Professional Manufacturer of Vacuum Hot Press Machine-QICEQUIP Established in 2008, QICEQUIP is specialised in vacuum hot press machine, vacuum welding oven, baking glue machine screeding machine equipment manufacturer. The company integrates R&D, production and sales, and is a brand enterprise in the field of manufacturing vacuum hot press bonding equipment in China.

Our advantage

Foreign trade cattle is based on the premise of big data analysis

Foreign trade cattle is based on the premise of big data analysis

Foreign trade cattle is based on the premise of big data analysis

Foreign trade cattle is based on the premise of big data analysis

During the charging process, some lithium ions in lithium iron phosphate are removed and transferred to the negative electrode through the electrolyte, which is embedded in the negative electrode carbon material; At the same time, electrons are released from the positive electrode and reach the negative electrode from the external circuit, maintaining the balance of chemical reactions. During the discharge process, lithium ions detach from the negative electrode and reach the positive electrode through the electrolyte. At the same time, the negative electrode releases electrons, which reach the positive electrode from the external circuit and provide energy to the outside world.

pipes are suitable for car size four or six piston brake

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification

pipes are suitable for car size four or six piston brake

TEI brake pads, brake discs, and brake steel pipes are suitable for car size four or six piston brake calipers. P60ES is equipped with 355 discs (18 inch front wheels) for modification